|

NEW FIB AutoGrid Rings & C-clipsNanoSoft's patent (pending) FIB AutoGrid Rings are a superior alternative for clipping FIB grids for use in Thermo Fisher Scientific (TFS) Cryo-FIB systems, and offer several major improvements over standard TFS FIB rings. These rings have a significantly increased area of the grid accessible for ion beam milling. Typical FIB rings have a small cut-out notch on the back, flat side of the ring to allow for shallow-angled ion beam milling on a limited portion of the grid. On the other hand, the “backside” of these FIB AutoGrid Rings have an angled face around the entire circumference, providing a substantial increase in milling area, reclaiming valuable sample/cells on your grid. These FIB AutoGrid Rings also have high contrast orientation marks, making correct visual orientation easy without the need to manually mark the ring with a marker, as is often the case with the less visible markings of standard TFS FIB rings. These FIB AutoGrid Rings also have matching marks on the "top face", so you can see the orientation of the ring when clipping a grid. These FIB AutoGrid Rings are manufactured with the same cutting-edge manufacturing techniques and quality control as our "regular" AutoGrid Rings (#47000-650), resulting in superior quality, reliable, and consistent parts, all while being more affordable than our competitors. Key features:

For use in TFS Aquilos, Helios, Hydra, Arctis, Scios. Available in packs of 100 FIB AutoGrid Ring & C-clip pairs (#47000-652) or packs of 100 C-clips only, without rings (#47000-651). |

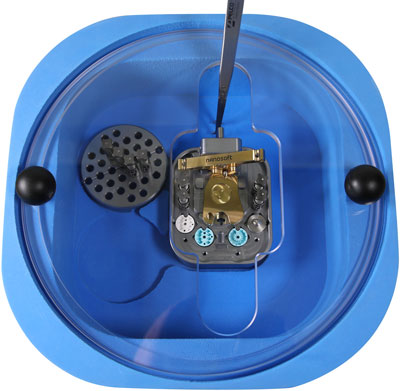

Clipping StationNanoSoft’s Clipping Station provides unmatched ease of use and efficiency for the clipping of Cryo-EM grids (known as AutoGrids) for Thermo Fisher autoloader-based microscopes. |

||||||

|

||||||

|

A high quality foam dewar integrates grid box and clipping tool access directly adjacent to the clipping space, increasing ease of use and reducing the potential for contamination. Furthermore, the Clipping Station comes with a puck sized holder for clipping tools, such that up to 33 tools can be pre-loaded with c-clips and placed in the holder to be cooled down while in a position that is easy to access, enabling seamless clipping of up to 33 samples at one time. A new Clipping Hub design makes the workflow easier, and a well-designed lid balances ease of use and protection. The opening in the lid provides the ideal amount of space to access the entire clipping hub without needing to rotate the lid, and while providing protection from ambient humidity. Knobs on the lid enable easy turning to access and transfer other grid boxes or clipping tools to the Hub, and a Lid insert can cover the entire opening so that the clipping space can be closed off from the ambient environment completely during cool down and as needed. Furthermore, the Clipping Station is compatible with both NanoSoft (#47000-611) and Thermo Fisher clipping tools. Clipping Station Features:

Other clipping stations typically utilize a rotating brass guidance cylinder, which is often difficult to turn and can bend tweezers. The clipping hub of this station utilizes a novel ‘seesaw’ mechanism for moving the guidance cylinder into and out of position. This mechanism requires the user to push down on either side of the cantilever beam to move the guidance cylinder into the position for clipping or for placement/removal of the AutoGrid ring. The shallow hole where the AutoGrid ring is placed for clipping has a dark colored surface to provide better contrast and tracking when placing an AutoGrid ring and picking up a clipped grid with AutoGrid tweezers. Clipping Hub Features:

|

Clipping Tool (#47000-611) |

Clipping ToolsNanoSoft’s Clipping Tool is loaded with C-clips and clips grids the same way as the Thermo Fisher version, and is compatible with the Thermo Fisher clipping station. The difference is that instead of ejecting the C-clip by pressing a long plastic handle, you press on the tool with a pair of tweezers. This version has the advantage of a compact design so that when they are placed in LN2 in the clipping station to be cooled down, the entire body is deep enough inside the station that they are untouched by any frost from environmental moisture, even when left in the station at cryogenic temperature for long periods of time. This means you can pre-load as many of the tools with C-clips as you would like, cool them all down at the same time, and then clip all your grids at one time without with little consideration for ice contamination - no need to warm, re-load and re-cool clipping tools. After loading the Clipping Tools with C-clips, place them into the Clipping Tool Rack, and then place the rack with Clipping Tools into a clipping station for cooling. These tools can be placed directly into the NanoSoft Clipping Station (#47000-615) without the need for the supplemental rack. When ready to clip, use any type of tweezer to grab the back end of the Clipping Tool - the square profile of the plunger/back end enables simple and comfortable grasping with tweezer tips. Small protuberances provide extra support to keep the Clipping Tool from twisting when transferring from the rack to the grid. We recommend using AutoGrid Tweezers - the Clipping Tools remains very securely in position during the transfer. Place the Clipping Tool into position for clipping and release the tool; we recommend pressing down on the top of the Clipping Tool to eject the C-clip and clip the grid, i.e. not while grasping the sides of the plunger with the tweezers. This will help you ensure that you can keep the tweezers straight while pressing the plunger - you will find that the shorter body of the Clipping Tool enables you to keep the tool straighter than competitor clipping tools while clipping, which helps ensure that C-clip properly seats into the AutoGrid ring. The C-clip Bottoming Tool provides an easier and more efficient way to "bottom" the C-clip at the tip of the barrel of a clipping tool prior to clipping. After pressing the C-clip into the barrel of the tool, instead of pressing the tip of the barrel against the tabletop or a pair of tweezers to push the c-clip to the tip of the barrel (by pressing the plunger), you place the barrel into the Bottoming Tool and press the plunger of the tool to bottom the C-clip. The cylinder of the Bottoming Tool ensures that the barrel of the clipping tool is straight, so upon pressing of the plunger to push the C-clip to the tip you are much less likely to "mis-bottom" the C-clip. Often when pressing the tip against the table top or another flat surface, you are not able to hold the barrel exactly straight against the surface and you the c-clip can fly out of the tool and is lost. The Bottoming Tool provides an easy way to ensure you don't mis-bottom C-clips anymore. 47000-612 Kit Contents: |

|

Clipping Tool Rack (#47000-613) shown with Clipping Tools |

||

(#47000-614) |

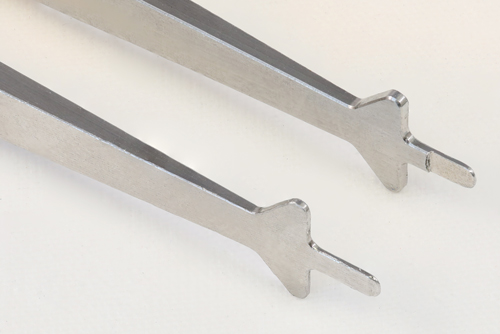

Shown with standard handle (#47000-600) top, self-closing handle (#47000-605) at bottom |

AutoGrid TweezersThe AutoGrid Tweezers are designed to handle the Thermo Fisher/FEI AutoGrids. The tweezer tip has a step cut out that enables the user to securely hold the AutoGrid while transferring it from the clipping station to the cassette. Available with both standard (#47000-600) and self-closing handles (#47000-605). |

|

|

AutoGrid Inspection ToolNanoSoft's AutoGrid Inspection Tool is a low-cost way of performing a last autogrid inspection step prior to loading them into the cassette. It is placed into a grid box spot in the Thermo Fisher/FEI cassette loading station and will remain there securely due to the spring-loaded detent on the side of the tool. AutoGrids can be placed in the groove of the AutoGrid inspection tool and quickly flipped back and forth to check that the grid is securely clipped. It provides a final, low-cost check to help ensure only well-clipped grids are loaded into the autoloader, saving the potential disaster of a poorly clipped grid coming undone in the autoloader and weeks of downtime. |